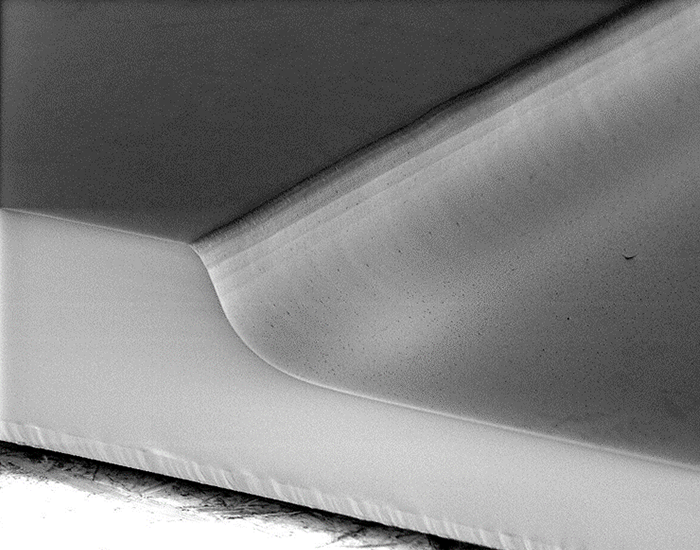

Fabricating beautiful and smooth cavities onto glass workpieces

Glass cavity etching process:

Etching the glass workpiece without penetrating the bottom side of the workpiece so as to form cavities (cavity depth adjustable).

This process is often adopted for workpieces such as OLED cap glass, because with chemical etching, this process is capable of fabricating flawless and smooth cavities which are exquisitely transparent and able to transmit lights without distortion.

Features

Standard specifications

| Glass type | Soda glass, Non-alkali glass, etc. |

|---|---|

| Processable size | ≦730 × 920mm |

| Thickness | 0.05〜2.0mmt |

| Cavity size | φ10μm |

| Cross-sectional shape | Tapered shape |

Differing from mechanical processes, NSC’s chemical process is capable of flawless, smooth finishing on the cavities.

Uses and Applications

Specific Examples

- For displays: Cap glass for OLED

- For vehicles: Cover glass for center information displays

- For semiconductors: Sensors

- Materials and parts for laboratories