NSC’s proprietary recycling system

Chemical peeling, sorting, and recovery

Our resource recycling is characterized by a treatment method that combines advanced chemical peeling technology with advanced cleaning technology.

Therefore, it is possible to recover scarce resources with high purity and reuse them as materials.

Recycling based on a recycling-oriented society

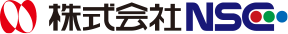

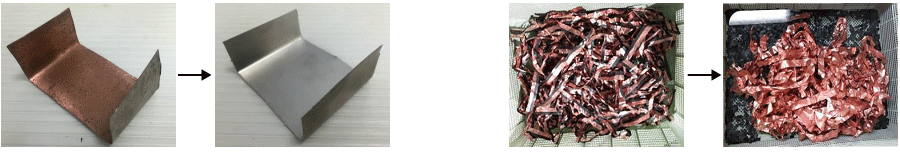

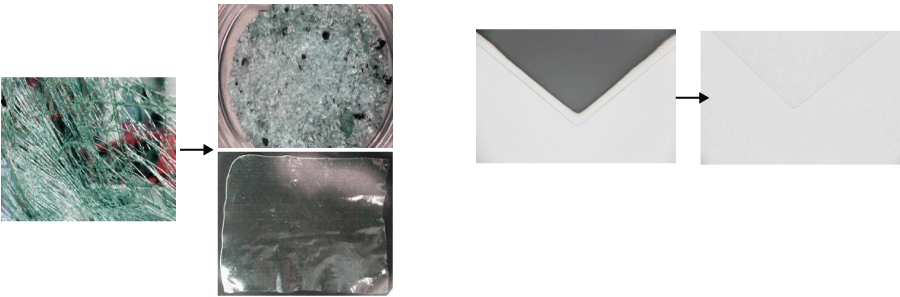

Recycling example

Chemical peeling technology to clean separate composite materials.

Defective boards and used dummy boards that have been discarded so far can be reused through this treatment, and industrial waste and its disposal costs can be reduced.

●Copper+SUS composite material → Copper Recovery/SUS Regeneration ●Anode material copper foil → Copper/Carbon Recovery

●Composite material of glass + resin→Glass cullet/resin recovery ●Plate glass + film formation→ Deposition peeling / Plate glass recovery

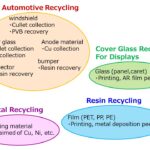

Automotive Recycling/Resin Recycling/ Metal Recycling/Display Recycling

Recyclable Resources

Metal

| Base Metal | Fe, Cu, Zn, Pb, Al |

| Precious Metal | Au, Ag, pt, Pd |

| Rare Metal | Li, Ti, Cr, Co, Ni, Nb, Mo, W |

Polymer

| PE, PC, PP, PS, PMMA, PI, PVB |

Glass

| Soda Glass, Non-alkaline glass, quartz、, Synthetic quartz, Aluminosilicate |

Sizes and shapes that can be accommodated

Board sizes are up to 1,100 mm × 1,300 mm, and it is also possible to handle large board sizes.

| Size | Glass-metal film substrate results 1,100mm × 1,300mm (maximum) |

|---|---|

| shape | Plate-like (including sheet), cullet, granular, powdery, thin film, foil film |

※Please consult us about other sizes and shapes.

Materials We can recycle

◆Lithium-ion battery(LiB)◆Electronic components, electronic substrates

◆Film printing shear ◆Automotive windshields,Rear glass ◆MLCC

We support companies that are working from “discarding” to “recycling”

Do you have any worries like this?

・I want to reuse printing and coating with defective processes, and processed films, sheets, and substrates.

・We want to recover rare metals used for plating and vapor deposition with high purity.

・We want to take environmentally friendly measures by reducing waste.

Please contact us if you want to recycle resources such as glass, metal, and various resins!

3R Activities

By reduce, reuse, and recycle parts and materials containing scarce resources,

We will actively work toward a recycling-oriented society and strive to preserve the global environment and use resources sustainably.