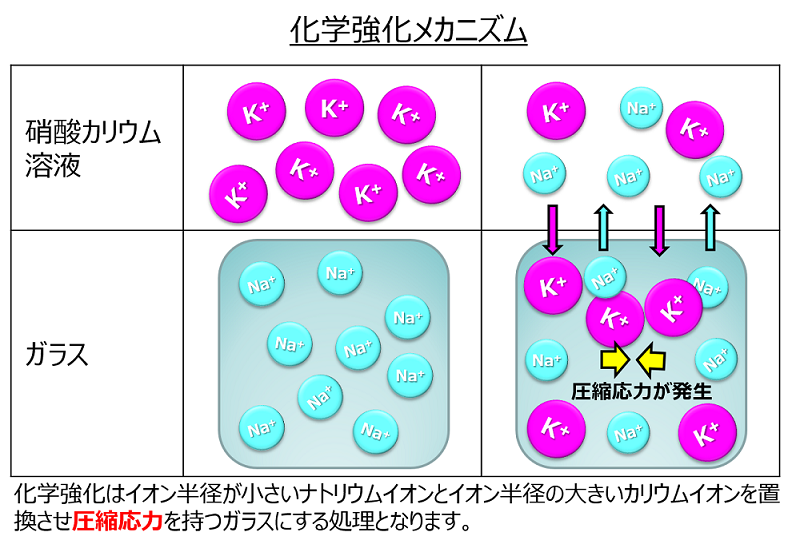

High strength of a glass workpiece can be achieved through chemical strengthening.

Chemical strengthening is a method in which the glass surface is strengthened by using chemicals to cause exchange of sodium ions and potassium ions of the glass surface, so as to form a compression layer on the glass surface.

A chemically strengthened glass workpiece has higher bending strength than an ordinary glass workpiece. Scratch resistance is also one of its features.

Glass workpieces slimmed and chemically strengthened by NSC have been highly evaluated by the users and are now being adopted as protective glass for smartphones and displays.

Features

Improving Strength

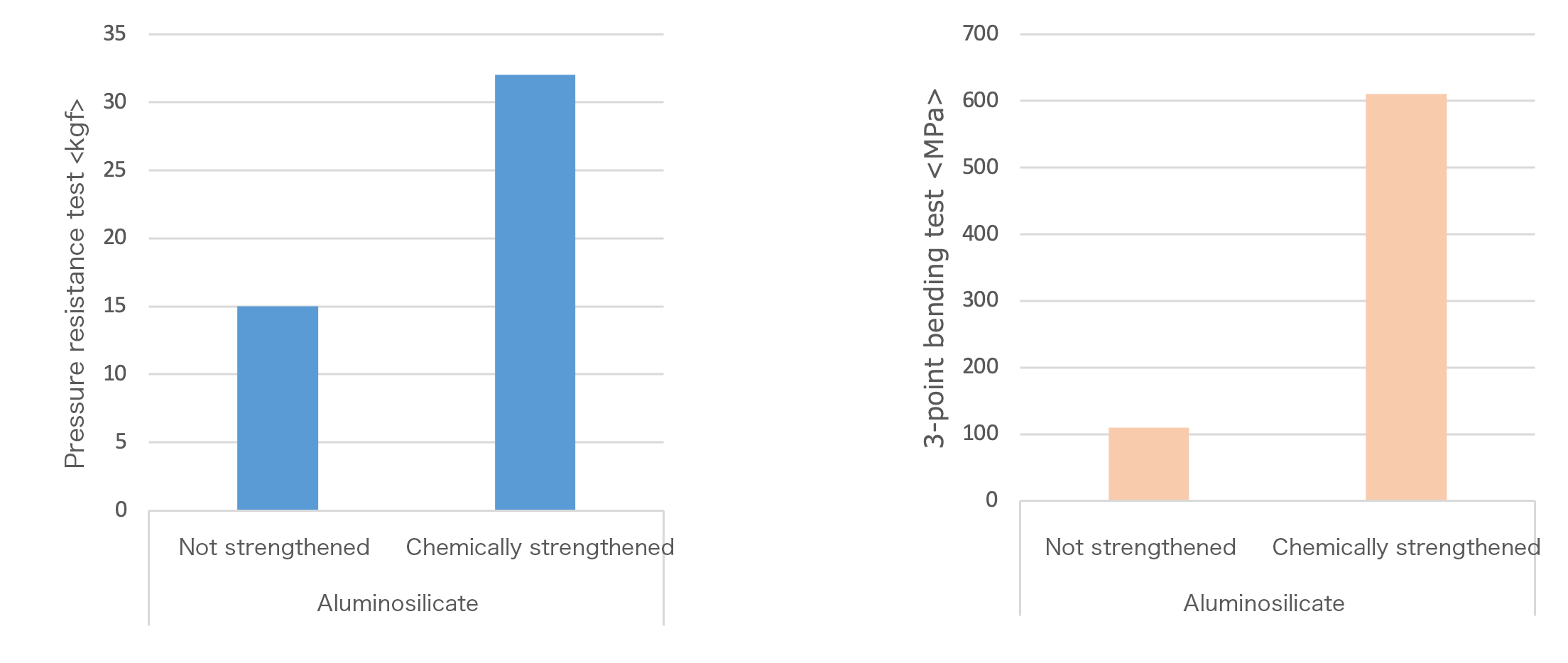

This process is capable of improving the strength of glass to an outstanding level. The following shows the measurement result in NSC’s tests on chemically strengthened aluminosilicate glass samples.

| Pressure resistance test |

3-point bending test |

||

|---|---|---|---|

| Aluminosilicate | Not strengthened | 15 | 110 |

| Chemically strengthened | 32 | 610 |

This process can be performed on different workpieces with a wide range of size and thickness.

| Glass type | Soda glass, Aluminosilicate glass |

| Size | 35 × 50mm ~ 1,000 × 1,000mm |

| Thickness | 100μm ~ 2,000μm (Records of thickness within 200μm are from our trial runs) |

*We also welcome inquiries about other glass types and thickness, as well as the etching depth.

Process flow

Uses and Applications

Specific Examples

- Cover glass (for various kinds of displays, for protective cover glass and lighting equipment, etc.)