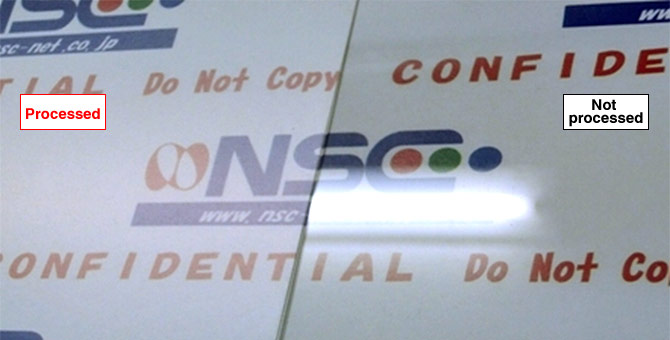

Controlling the reflection of the likes of sunlight to give glass an anti-glare effect

A chemical-based surface treatment (chemical AG process) is applied directly to the surface of glass to form microasperities and give the glass an anti-glare effect under the likes of sunlight.

The advantages of performing AG process directly onto a glass workpiece

| Glass | Resin plates, coatings, films | |

|---|---|---|

| Excellence in design | NSC’s AG process is able to keep the beauty and high-quality texture which belong to the unique properties of glass workpieces. | Looks whitish and cheapened on some occasions. |

| Heat resistance | No deformation will occur while the heat is kept within 600℃. → Applicable in the situation where heat-resisting or flame-resisting materials are required. |

Most of the materials start to change in quality under the heat with a range from 80℃ to 120℃. |

| Chemical resistance | The glass surface has high resistance to various kinds of chemicals. → Applicable to the environment involved with chemicals. |

Chemical degradation occurs when contacting with organic solvents. |

| UV resistance | No chemical change → No change in quality even after a long-term use in outdoor spaces |

The color may turn yellow under the effect of UV radiation. |

| Friction durability | Pencil hardness of at least 9H → Nearly no change in quality at locations where the products are frequently touched or rubbed. |

Hardness scale of most of the products is ranged from 2H to 6H. |

Features

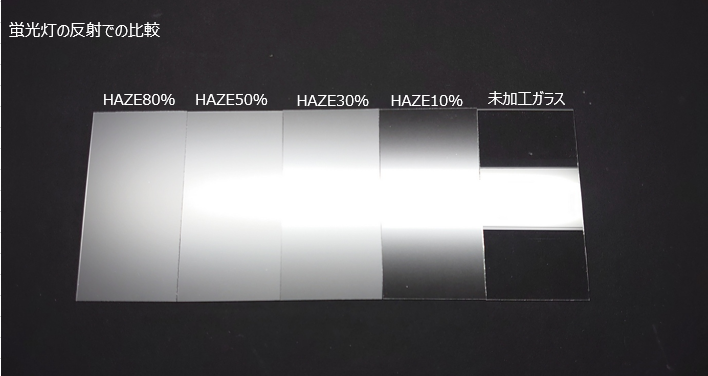

NSC’s AG process is able to control the haze within a range of 1%~ 90%.

NSC’s AG process is able to control the haze within a range of 1%~ 90%.

Appearance of the workpiece is adjustable according to the purpose of use. Contact us for details.

Excellent Writing Touch with Stylus

A person using a stylus to write on glass treated with the AG process will experience the same sensation as they would when using a pencil.

Available Sizes

The AG process can be applied to glass substrates with a size of up to 730mm × 920mm.

Optional Processes

Optional processes including ion exchange glass strengthening (as postprocessing), curving, and printing are also available.

Uses and Applications

Specific Examples

- Cover glass for displays (for vehicles and industrial machines)

- Diffusion covers for LED lighting fixtures

- Window glass

- Molds (application)

- Solar cells